Tuesday July 1, 2008. Visit, waited so much, with the Hangar.

It is also a commemorative day: A Zeppelin planed above Switzerland to commemorate the first overflight of the country by an airship July 1, 1908. Like its ancestor, the NT4 flew of Friedrichshafen to Lucerne before turning over to Germany. Apparently, Wolfgang von Zeppelin, a descendant of the inventor, was on board NT4 for this commemorative flight. But we did not meet it. |

| |

The hangar of the Zeppelin NT is the largest in Southern Germany, measuring 361ft in length, 226ft in width, and 105ft in height.

Technical Data of the Zeppelin NT 07 :

Engines Propulsion: 3 x 147 kW/197 hp each (Textron Lycoming - IO-360)

Length : 75 m (246 ft)

Max. width : 19.5 m (64 ft)

Height : 17.4 m (57 ft)

Envelope volume : 8,425 m³

Max. take-off weight: 8,040 kg (17,688 lbs)

Payload : 1,900 kg (4180 lbs)

Max. cruising speed : 125 km/h (78 mph)

Max. flight : 2,600 m (8,530 ft)

Max. flight duration: about 24 h

Range : 900 km (486 NM)

|

|

| |

|

|

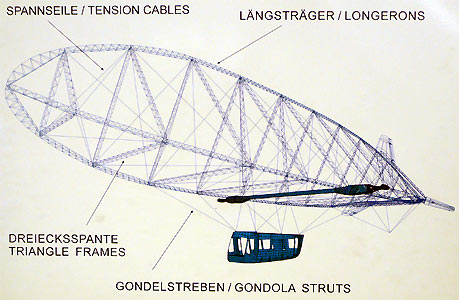

The structure has to connect rigidly the main components and to carry the airloads : Nose cone - Empenage - Gondola - landing gears - Engines

The very stable primary structure is a lightweight with a weight of approx. 1,000 kg (approx. 2,200 lbs). |

|

| |

It consists of rigid structure : 3 Aluminium longerons and 13 triangles frames in carbon-glas technology tensed up with Aramid tension cables.

Total weight : ca. 1000 kg and total length of all frames : 2.000 m |

| |

The necessary lift is generated by non-flammable helium enclosed by a newly developed envelope material made of tearproof and high-strength multilayer laminate. Even a lightning strike will not considerably effect the flight characteristics. The envelope has a slight superpressure of 5 mbar. Ballonets inside the envelope keep the internal pressure constant in each flight situation. |

|

| |

|

|

The materials used for this envelope :

External layer : Tedlar (protective film UV-proof)

Intercellular layer: Polyester fabric (tear-resistant)

Internal layer : Polyurethane (weldable and leak-proof)

Weight : 250 Gramm/m2

Total surface area of NT : 2.400 m2

Tear strenght : 285 N/cm (28.5Kg/cm)

Manufacturer : ILC , USA

Final adjustment and pressure test are performed in Friedrichsafen.

|

| |

|

ILC was responsible for the detailed design, materials development, and fabrication of the new LZNO7 airship envelope for Zeppelin. The airship received its certification in 2001. ILC Dover has been developing and manufacturing the softgoods structures for aerostats, airships, blimps, and other lighter-than-air vehicles since the early 1970's . More : www.ilcdover.com/index.cfm |

| |

|

|

|

| |

|

The cockpit is a neat high-tech workplace equipped with latest avionics.

"Fly-by-wire" control systems with a sidestick enable precise manoeuvres and relieve the pilots. A mission display is available as an option. The cabin can accommodate 2 pilots and up to 12 passengers. An adjustable cabin permits a quick conversion for the different missions. |

| |

|

|

|

| |

|

|

| Overall picture of the interior of the hangar. With foreground the fourth of the series Zeppelin. With the colors of “Stella Artois” for his London estival round and Airship Ventures to leave to the autumn to the USA. Behind, Zeppelin for the flights of Friedrichshafen. Photo of right-hand side: anchoring in the Hangar. |

| |

|

|

|

|

|

| |

|

Three propellers with a swivel angle of up to 120 degrees and a lateral fan, which is driven by the rear engine, gives the airship unmatched maneuverability and an unrivalled, economical flight. |

|

The capabilities of a vertical take-off, a precise landing, hovering on one spot and a backward flight are the unique flight characteristics enabled by the swivelling propellers.

Two lateral an one rear engine with 200 hp each provide the propulsion and a possible maximum speed of 125 km. The engines are placed well above the cabin giving the passengers the feeling of nearly silent flying .

The densitiy of helium is 7-times less than of air. 1m3 Helium can lift a load of 1Kg Inert gas, doesn’t react wiht other elements Colourless – Odourless – Not flammable

Extracted from natural gas sources, found in USA, Kasachstan and Algeria. Helium storage is done on site in a special storage tank for 3.500m3 of Helium up to 40 bar.

Volume of Helium inside the Zeppelin-NT is approx. 7.400m3 Helium cleaning will be done with special filtering units |

|

| |

|

|

|

The day of our visit : purification of Helium after the flight of the two Zeppelins, the evening with the Hangar. System of purification in container |

| |

|

|

| |

|

| The below pictures show details of the parts and material stored in the Hangar. We can easily take photographs. Our only regret is not to have had access to the ground of take-off for make a photo of the hangar in his totality. |

| |

|

|

|

| |

|

|

| The valve is used to evacuate the air, during the flight, contained in the small baloons in order to control the pressure. More the air and quickly evacuated more the dirigealbe goes up quickly. It can reach 10m/s at the time of the rise and 8m/s to the descent. |

| |

|

Various spare parts stored in the Hangar |

Winnow water filling which will be used for the unballasting of the airship. |

| |

|

|

| |

|

|

|